80 BILLION SQUARE METERS OF EXCESS FABRIC ARE SENT TO LANDFILLS EACH YEAR.

Unless a product is designed for zero-waste production, it is impossible to avoid cutting scraps. The larger the quantity of apparel produced, the larger the amount of deadstock or leftover textile waste that is sent to landfills. The amount of underutilized fabrics sent to landfill will continue to grow unless we begin to reevaluate what "waste" actually is.

Source: Reverse Resources

INDONESIA IS THE WORLD’S SECOND LARGEST OCEAN POLLUTER.

As a developing nation, Indonesia faces many challenges. Inadequate waste management services – yet alone awareness – plague the archipelago, allowing the country to become the world’s second largest ocean polluter. The capital of Jakarta produces a staggering 7000 tons (28.5% plastic) of waste each day. Of the collected trash, only an abysmal rate of 7.5% (2% in rural regions) gets recycled. Currently, Indonesia does not have the proper resources to tackle this growing waste epidemic.

Source: Statista, Kompas, Global Recycling

3.3 BILLION METRIC TONS OF CARBON DIOXIDE WAS EMITTED BY THE APPAREL INDUSTRY IN 2016.

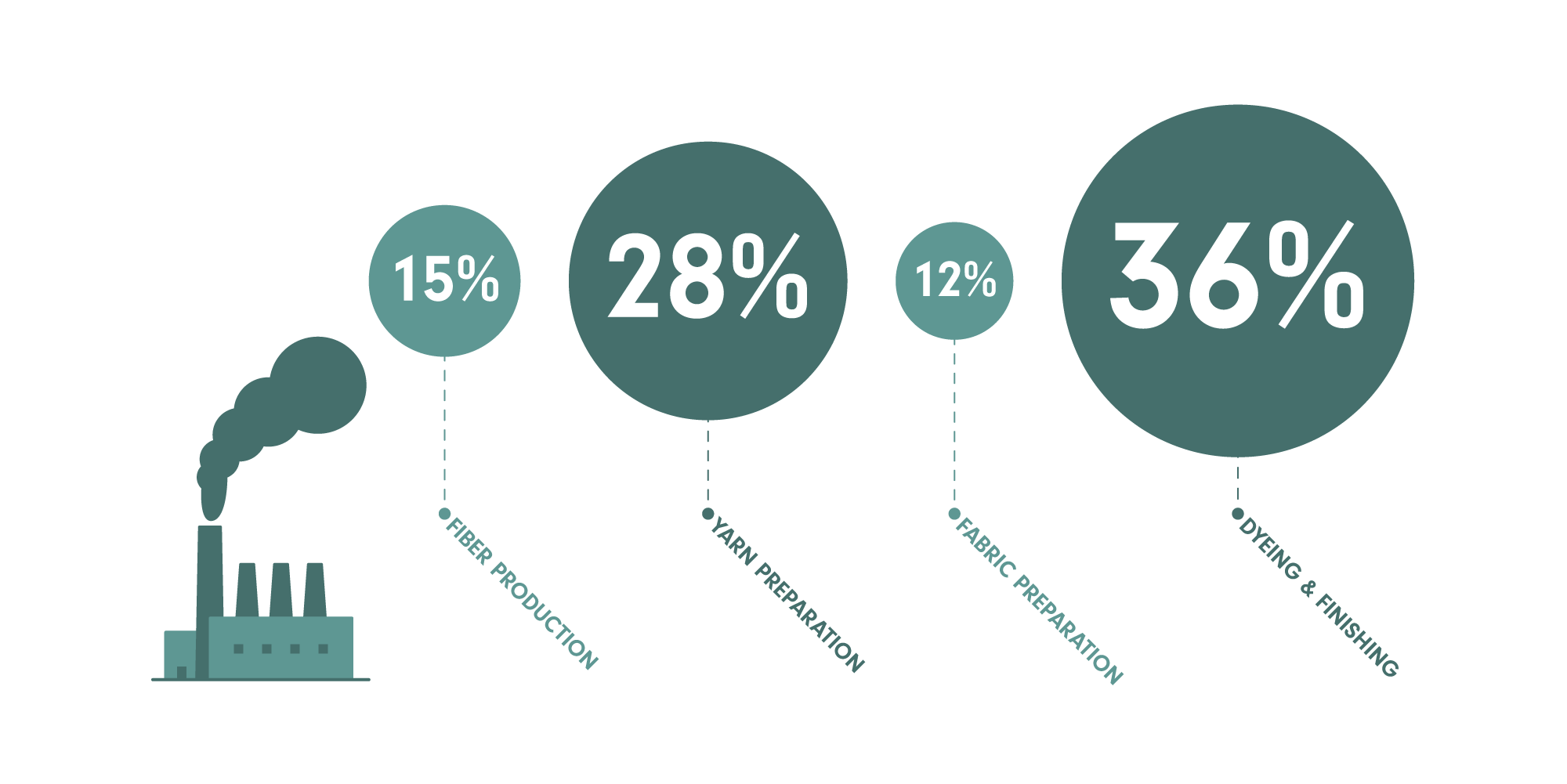

The apparel industry alone represents 6.7% of global greenhouse gas (GHG) emissions. The majority of this impact occurs during textile manufacturing, before the assembly of the garment even begins. With global manufacturing concentrated in Asia, GHG emissions in these stages are driven by apparel manufacturing’s reliance on hard coal and natural gas to generate electricity and heat.

Source: Quantis

60 MILLION WORKERS ARE EMPLOYED (AND GENERALLY EXPLOITED) BY THE GARMENT INDUSTRY.

Do you know how your product was made? Where did it come from? Who made it? Did you know that 80% of the garment industry workforce is composed of women between the ages of 18-35. As one of the world's largest industries, the garment sector consistently exploits cheap labor and violates human rights in many countries across the globe (mostly in developing nations, but even the United States is not immune to this).

Source: LA Times, Fashion United

Our Solution.

You deserve to know how your product was made.

TOPIKU MEANS "MY HAT" IN INDONESIAN.

In 2014, while volunteering at a non-profit in his home country of Indonesia, our founder Monty Hasan had the opportunity to visit local villages and meet with artisans who crafted bags from upcycled materials. This inspired him to create TOPIKU.

Our sustainable hats are responsibly crafted from upcycled and recycled waste materials, all sourced through traceable methods. Over the years, we have maintained close relationships with our artisans and suppliers to ensure we know the exact conditions of our supply chain.

We create eco-friendly caps that support our mission of sustainable development:

HDPE PLASTIC RECYCLING – BUCKET TO BRIM

CIRCULAR PRODUCTION METHODS

With each hat, we carefully evaluate alternative, responsible material sources. Buckets are salvaged from landfills and recycled into brims. Leather scraps are collected from local businesses and then recut into patches and straps. Fabrics are upcycled directly from garment manufacturers' leftover or deadstock textiles.

This process allows us to divert material from ending up in landfills. Since we don’t order any new fabrics, we eliminate the need for the energy- and water-intensive stages of fiber, yarn, fabric, and dyeing production – helping us to significantly reduce our carbon footprint. It’s an exploration of how the waste byproducts of one industrial process can find a second-life and become the inputs to another product.

By encouraging our manufacturers to reuse waste materials, they can begin to reevaluate what “waste” truly is and see the potential of reuse.

PAK AGUS – OUR SEWING MACHINE OPERATOR

ARTISAN EMPOWERMENT

TOPIKU utilizes ethical craft rather than "sweatshop" garment factories commonly employed by fast-fashion brands across the world. Since 2015, we have worked together with local home industries in the village of Desa Rahayu in Cigondewah, West Java, Indonesia to produce all of our hats.

Home industries allow men and women to work from the comfort of their own home, participate in a closely-knit community, and provide them a platform to share their craft through their specialized skills.

We offer both men and women equitable work opportunities and pay them living wages. This reliable pay we provide allows for wage resilience – even in the face of the pandemic – to show artisans the financial benefits of creating eco-friendly products.

Our commitment to industrial ecology will form the basis for long-term sustainable environmental, social, and economic growth in these developing communities.

BLI FABI - A SUNGAI WATCH RIVER WARRIOR

SOCIAL & ENVIRONMENTAL PROTECTION

Our impact does not stop at our supply chain. We go above and beyond to ensure that we can play our part in making a difference in communities outside of our own. We purchase certified carbon offsets to mitigate the emissions we cannot offset.

We know that TOPIKU can’t single-handedly win the fight against plastic pollution and fast-fashion, which is why we collaborate with, sponsor, and support various non-profit organizations across the globe. It’s all about localized impact.

We are big believers in the power of business as the catalyst for sustainable change.

United Nations Sustainable Development Goals

Changing the world starts with changing your world.

We have built TOPIKU to be a social enterprise that can lead by example – powered by responsible business practices that can positively impact the communities we work with.